ASTM A335 P91 alloy steel pipe is a highly specialized type of pipe widely used in high-temperature applications.

ASTM A335 / ASME SA335 Pipe named chrome moly pipe as they have a high level of Chromium and Molybdenum.

Chromium will increase oxidation resistance and provides high-temperature strength, along with the better tensile & yield strength and proper hardness at room temperature. When the chromium content increased more than 12%, it can be classified as stainless steel.

Molybdenum increases the overall strength, resistance, elasticity, hardenability and overall quality, moly ensures that the material is more resistant to softening, restrains the growth of grains and lessens the chances of embrittlement. It is the single additive that is responsible for the increase in high temperature resistance (to 540-750°C) and it also improves the corrosion resistance to steel.

What is a P91 pipe?

ASTM A335 P91 pipe is a type of high-temperature alloy steel pipe, used in applications requiring excellent strength and resistance to creep at elevated temperatures, commonly found in power plants for critical components like boilers and heat exchangers.

High-temperature application:

P91 is specifically designed to maintain strength at very high temperatures, making it suitable for extreme conditions in power generation.

Creep resistance:

This alloy has excellent resistance to “creep,” a phenomenon where a material slowly deforms under constant stress at high temperatures.

Chemical composition:

The “P91” designation refers to its primary alloying elements: 9% chromium and 1% molybdenum.

Standard specification:

P91 pipes are typically manufactured according to ASTM A335 standard.

What is ASTM A335 P91 material?

ASTM A335 P91 is a ferritic alloy steel that’s used for high-temperature applications. It’s also known as 9 Cr 1 Mo steel or chrome moly pipe.

Composition

Carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, vanadium, nitrogen, nickel, aluminum, columbium, titanium, and zirconium

Properties

High strength

Creep resistant

Resistant to corrosion, oxidation, and erosion

Can withstand temperatures up to 600 °C

Has a minimum yield strength of 415 MPa and a minimum tensile strength of 585 MPa

Uses power plants, chemical plants, and other industrial facilities.

Pipe types

Seamless pipes are drawn from a single billet of raw material

Welded pipes are welded from a strip or sheet

Other designations UNS #: K91560, ASME Specification alloy steel Pipes, and ASME SA335 Grade P91 Pipes.

Heat treatment

The pipes are normalized at 1500°C to enhance creep strength and durability

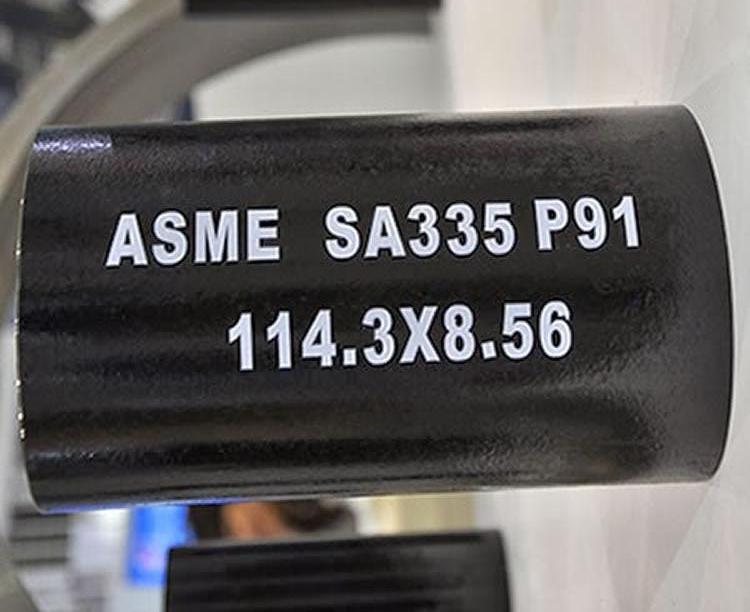

ASTM A335 P91 Pipe Specification

| Specification | ASTM A335 / ASME SA335 |

| Grades | ASTM A335 P5, ASTM A335 P9, ASTM A335 P11, ASTM A335 P22, ASTM A335 P91, ASME SA335 P5, ASME SA335 P9, ASME SA335 P11, ASME SA335 P22, ASME SA335 P91 |

| Type | Seamless – Hot Rolled / Cold Drawn |

| Outer Diameter Size | A335 – 3/8″ NB to 30″ NB (Nominal Bore Size) |

| Wall Thickness | Schedule 20 to Schedule XXS (Heavier On Request) Up to 250 mm Thickness |

| Ends | Plain Ends / Beveled Ends / Coupling |

| A335 P92 Alloy Steel Seamless Pipes Coating | Epoxy Coating / Colour Paint Coating / 3LPE Coating. |

Standard Scope

This specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high-temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

Materials and Manufacture

Pipe may be either hot finished or cold drawn with the finishing treatment as required.

Heat Treatment:

All pipe shall be reheated for heat treatment and heat treated in accordance with the requirements of Table 2.

NOTE 3—It is recommended that the temperature for tempering should be at least 100 °F [50 °C] above the intended service temperature; consequently, the purchaser should advise the manufacturer if the service temperature is to be over 1100 °F [600 °C].

NOTE 4—Certain of the ferritic steels covered by this specification will harden if cooled rapidly from above their critical temperature. Some will air harden, that is, become hardened to an undesirable degree when cooled in air from high temperatures. Therefore, operations involving heating such steels above their critical temperatures, such as welding, flanging, and hot bending, should be followed by suitable heat treatment.

Alloy Steel P91 Pipes Chemical Composition

| Alloy Steel P91 | C | Cr | Mn | Mo | P | S | Si |

| 0.08-0.12 | 8.00 – 9.50 | 0.30-0.60 | 0.85 – 1.05 | 0.020 max | 0.010 max | 0.20 -0.50 |

Alloy Steel P91 Pipe Mechanical Properties

| Tensile Strength, MPa | Yield Strength, MPa | Elongation |

| 585 min | 415 min | 20 min |

ASTM A335 P91 Pipe Heat Treatment Requirements

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering |

| Temperature Range F [C] | |||

| P91 | Normalize and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

| Quench and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

What are the grades of ASTM A335?

ASTM A335 is a standard for seamless alloy steel pipes that come in many grades, including P1, P5, P9, P11, P22, P91, and P92. These pipes are used in many industries, including power plants, chemical plants, and nuclear reactors.

Common grades

P5: Used in the petrochemical industry

P9: Used in the petrochemical industry

P11: Used in power plants, nuclear reactors, and jet engines

P22: Used in power plants and chemical plants

P91: Used in power plants and chemical plants

P92: Used in high-pressure boilers for power generation

Properties

ASTM A335 pipes are made of chrome-molybdenum alloy steel, and are designed for high-temperature and high-pressure applications. They can be bent, flanged, and welded.

ASTM A335 Chrome Moly Pipe Dimension

| Referenced Weight Lists(ASME B 3 6 .1 0 M ) | kg | ||||||||||||||

| Nominal Size | OD | kg/m | |||||||||||||

| DN | NPS | OD | Sch10 | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch140 | Sch160 | XXS |

| 6 | 1/8 | 10.3 | 0.28 | 0.32 | 0.37 | 0.37 | 0.47 | 0.47 | |||||||

| 8 | 1/4 | 13.7 | 0.49 | 0.54 | 0.63 | 0.63 | 0.80 | 0.80 | |||||||

| 10 | 3/8 | 17.1 | 0.63 | 0.70 | 0.84 | 0.84 | 1.10 | 1.10 | |||||||

| 15 | 1/2 | 21.3 | 1.00 | 1.12 | 1.27 | 1.27 | 1.62 | 1.62 | 1.95 | 2.55 | |||||

| 20 | 3/4 | 26.7 | 1.28 | 1.44 | 1.69 | 1.69 | 2.20 | 2.20 | 1.90 | 3.64 | |||||

| 25 | 1 | 33.4 | 2.09 | 2.18 | 2.50 | 2.50 | 3.24 | 3.24 | 4.24 | 5.45 | |||||

| 32 | 1 1/4 | 42.2 | 2.70 | – – – | 2.87 | 3.39 | 3.39 | 4.47 | 4.47 | 5.16 | 7.77 | ||||

| 40 | 1 1/2 | 48.3 | 3.11 | 3.53 | 4.05 | 4.05 | 5.41 | 5.41 | 7.25 | 9.56 | |||||

| 50 | 2 | 60.3 | 3.93 | 4.48 | 5.44 | 5.44 | 7.48 | 7.48 | 11.11 | 13.44 | |||||

| 65 | 2 1/2 | 73.0 | 5.26 | 8.04 | 8.63 | 8.63 | 11.41 | 11.41 | 14.92 | 20.39 | |||||

| 80 | 3 | 88.9 | 6.45 | 9.92 | 11.29 | 11.29 | 15.72 | 15.72 | 21.35 | 27.68 | |||||

| 90 | 3 1/2 | 101.6 | 7.40 | 11.41 | 13.57 | 13.57 | 18.63 | 18.63 | |||||||

| 100 | 4 | 114.3 | 8.36 | 12.91 | 16.07 | 16.07 | 22.32 | 22.32 | 28.32 | 33.54 | 41.03 | ||||

| 125 | 5 | 141.3 | 11.57 | 21.77 | 21.77 | 30.97 | 30.97 | 40.28 | 49.11 | 57.43 | |||||

| 150 | 6 | 168.3 | 13.48 | 28.26 | 28.26 | 42.56 | 42.56 | 54.20 | 67.56 | 79.22 | |||||

| 200 | 8 | 219.1 | 19.96 | 33.31 | 36.81 | 42.55 | 42.55 | 53.08 | 64.64 | 64.64 | 75.92 | 90.44 | 100.9 | 111.3 | 107.9 |

| 250 | 10 | 273.0 | 27.78 | 41.77 | 51.03 | 60.31 | 60.31 | 81.55 | 81.55 | 96.01 | 114.8 | 133.1 | 155.2 | 172.3 | 155.2 |

| 300 | 12 | 323.9 | 36.00 | 49.73 | 65.20 | 73.88 | 79.73 | 109.0 | 97.46 | 132.1 | 159.9 | 187.0 | 208.1 | 238.8 | 187.0 |

| 350 | 14 | 355.6 | 54.69 | 67.90 | 81.33 | 81.33 | 94.55 | 126.7 | 107.4 | 158.1 | 195.0 | 224.7 | 253.6 | 281.7 | |

| 400 | 16 | 406.4 | 62.64 | 77.83 | 93.27 | 93.27 | 123.3 | 160.1 | 123.3 | 203.54 | 245.6 | 286.7 | 333.2 | 365.4 | |

| 450 | 18 | 457.0 | 70.57 | 87.71 | 122.4 | 105.2 | .155.8 | 205.7 | 139.2 | 254.6 | 309.6 | 363.6 | 408.3 | 459.4 | |

| 500 | 20 | 508 | 78.55 | 117.2 | 155.1 | 117.2 | 183.4 | 247.8 | 155.1 | 311.2 | 381.5 | 441.5 | 508.1 | 564.8 | |

| 550 | 22 | 559 | 86.54 | 129.1 | 171.1 | 129.1 | 294.3 | 171.1 | 373.8 | 451.4 | 527.0 | 611.6 | 672.3 | ||

| 600 | 24 | 610 | 94.53 | 141.1 | 209.6 | 141.1 | 255.4 | 355.3 | 187.1 | 442.1 | 547.7 | 640.0 | 720.2 | 808.2 | |

Permissible Variations in Outside Diameter of Alloy Steel Pipes

1) For pipe ordered to NPS [DN] or outside diameter, variations in outside diameter shall not exceed those specified .

2) For pipe ordered to inside diameter, the inside diameter shall not vary more than +/- 1 % from the specified inside diameter.

| NPS [DN] Designator | Over | Under | ||

| in. | mm | in. | mm | |

| 1/8 to 1 1/2 [6 to 40], incl. | 1/64 (0.015) | 0.4 | 1/64 (0.015) | 0.4 |

| Over 1 1/2 to 4 [40 to 100], incl. | 1/32 (0.031) | 0.79 | 1/32 (0.031) | 0.79 |

| Over 4 to 8 [100 to 200], incl. | 1/16 (0.062) | 1.59 | 1/32 (0.031) | 0.79 |

| Over 8 to 12 [200 to 300], incl. | 3/32 (0.093) | 2.38 | 1/32 (0.031) | 0.79 |

| Over 12 [300] | +/- 1% of the specified outside diameter | |||

What is the difference between A335 P91 Type 1 and Type 2?

A335 P91 Type 1 and Type 2 are both grades of alloy steel pipe under the ASTM A335 standard, but the main difference lies in their chemical composition, with Type 2 generally having stricter limitations on elements like manganese, sulfur, silicon, and nitrogen, resulting in enhanced creep strength and making it better suited for high-temperature applications with sustained stress; essentially, Type 2 offers improved performance under extreme conditions compared to Type 1.

Chemical Composition:

Type 2 has tighter tolerances on certain elements like manganese, sulfur, silicon, and nitrogen, leading to better creep resistance.

Application:

Type 2 is often preferred for applications requiring high creep strength, like power generation boilers and high-pressure pipelines operating at elevated temperatures.

Overall Performance:

While both types have excellent high-temperature strength and corrosion resistance, Type 2 generally performs better in demanding environments with sustained stress.

Key Features

Alloy Steel Composition:

P91 is a ferritic alloy steel, meaning it contains chromium and molybdenum, among other alloying elements.

The “91” designation indicates its specific chemical composition, which includes approximately 9% chromium and 1% molybdenum.

These additions provide enhanced strength, corrosion resistance, and high-temperature performance.

High-Temperature Service:

This pipe is designed for use in environments with extremely high temperatures, making it ideal for power generation, petrochemical, and other industries.

It exhibits excellent creep strength, meaning it can withstand high stresses over extended periods at elevated temperatures without significant deformation.

Seamless Construction:

ASTM A335 P91 pipes are typically manufactured as seamless pipes, which provides superior strength and resistance to pressure.

This is very important for high pressure applications.

Applications:

– Power generation

– Petrochemical plants

– Oil and gas industry

– High-temperature piping systems.

Key Advantages

Enhanced Creep Strength:

P91’s composition allows it to maintain its strength at high temperatures, reducing the risk of failure.

Improved Corrosion Resistance:

The chromium content provides excellent resistance to oxidation and corrosion.

Long Service Life:

Its durability and high-temperature performance contribute to a long service life, reducing maintenance and replacement costs.

You can get an offer for products in below material forms:

-Pipe and Tube (EN 10216-5, ASTM A213, ASTM A249, A312, A790,)

-Forged Fitting and Flange (ASTM A182 , ASTM A105,ASTM B564 )

-Butt Weld Fittings (ASTM A234, ASTM A403,ASTM A815)

-Round bar , Billet (ASTM A276, ASTM A479)

– Plate, Sheet, Strip(ASTM A240, EN 10028-7, A480)

-Bolting, Nuts(ASTM A193, A194, A320)

ASTM A335 P91 Alloy Steel Pipe Exported Countries

We Export ASTM A335 P91 Alloy Steel Pipe to Saudi Arabia, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen , Syria, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Cambodia, Argentina, Bolivia, Brazil, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Jamaica, Bahamas, Denmark, Norway, Germany, France,Italy, United Kingdom, Spain, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Finland, Ireland, Croatia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Europe, Africa, Asia, North America, South America, Middle East.etc

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....